Guangdong Inteam is a professional Chinese manufacturer and trading company of PVC blowing agent established in 1999. Please feel free to wholesale customized types of pvc foaming agent at competitive price from our factory.

Performance:

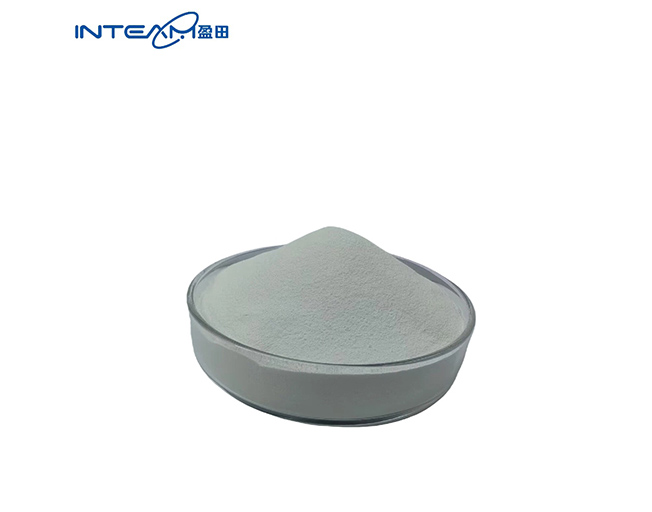

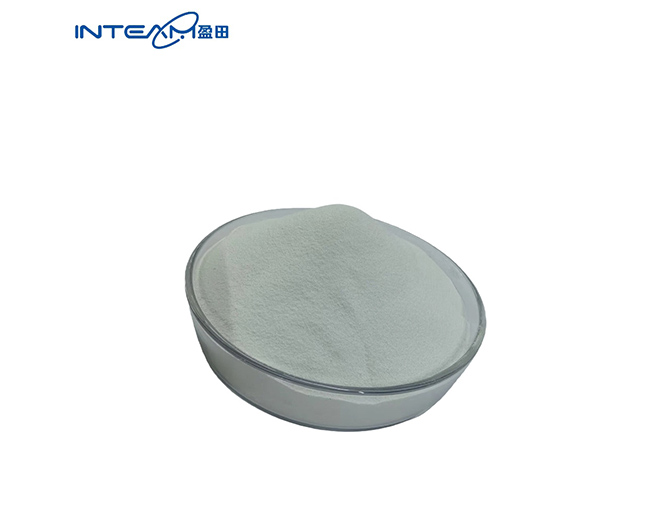

AC blowing/foaming agent is a yellow powder, but its decomposition residue is white, so it can be used in white or light-colored products. AC foaming agent itself is odorless, and its decomposition products are also odorless. The decomposition gas contains N, CO, CO2 and a small amount of nitrogen.

Product Features:

Good flow and dispersion properties, resulting in a smooth product surface.

No screw fouling, minimal product shrinkage.

Good product whiteness, fine and uniform cell structure.

Application Scope

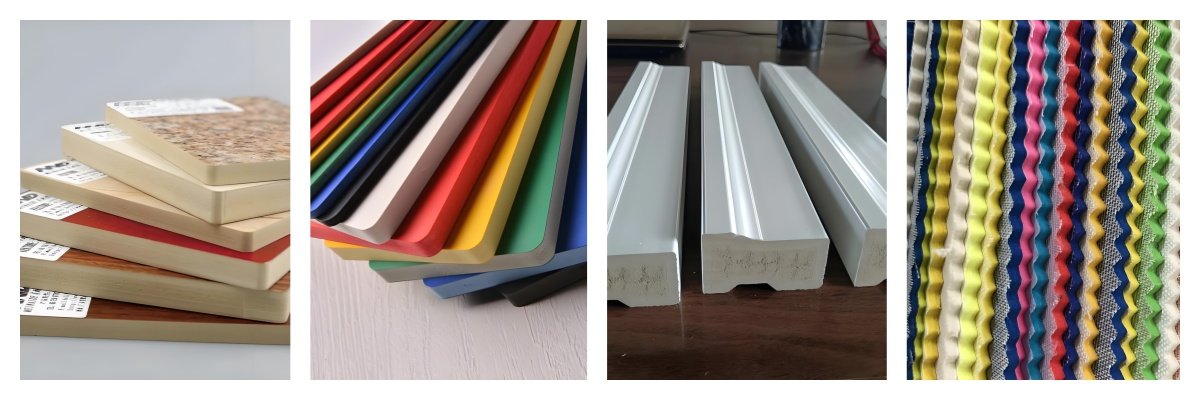

1 Plastic industry: Used in the production of polyethylene foam boards, polypropylene foam plastics, PVC foam slippers, foam floor mats, plastic foam packaging materials, etc.

2 Rubber industry: Suitable for foam molding of rubber shoe soles, rubber seals, sponge rubber products, tire buffer layers, etc.

3 Other fields: Can be used for foam materials for food packaging (must comply with food contact material standards), building insulation foam materials, foam components of sports equipment, etc.

Usage Methods

Adjust according to the product density requirements and base material characteristics. The conventional addition amount is 0.5%-3.0% of the base material mass:

1 Low-density products (high blowing/foaming ratio): 1.5%-3.0% addition amount;

2 Medium and high-density products (low blowing/foaming ratio): 0.5%-1.5% addition amount.

Packaging and Storage

- Packaging: 25kg paper-plastic compound bag.

- Storage: Store in a cool, dry and well-ventilated place. It is advisable to use up the product within one year.