Main Components:

Tribasic Lead Sulfate, Dibasic Lead Phosphite, Lead Stearate, Antioxidant, Lubricant, etc.

Physical Properties:

- Appearance: Flakes, white or lightyellow

- Lead Content: 20~40±1% or adjusted according to customer requirements

- Lubricant Content: 40~50% or adjusted according to customer requirements

- Antioxidant: Appropriate amount

- Heat-Resistant Additives: Appropriate amount

Characteristics:

- Excellent heat stability: The overall color of the product is uniform, with no yellowing at the edges or thick walls.

- Excellent fluidity: Reduces melt viscosity and extrusion torque, ensures smooth discharge, and effectively increases production capacity.

- Excellent gelation property: Improves melt strength, resulting in flat surface and good gloss of finished products, with no streaks or pits on the products.

- No exudation: No accumulation of exudates at the die head, and the mold removal interval is generally more than one month.

- Effectively reduces foaming temperature, achieves good foaming effect, and the product has a light specific gravity.

- Uniform and dense cell structure, no continuous voids or perforations.

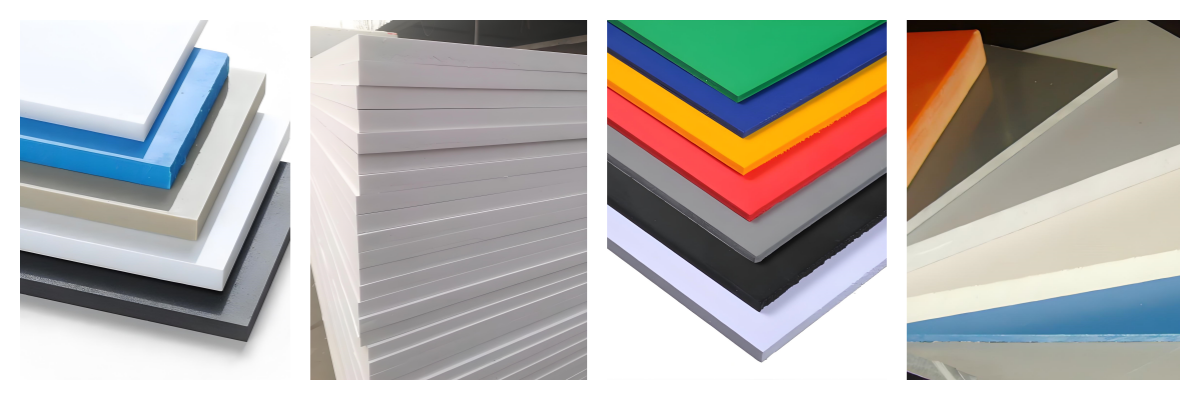

Applications:

Suitable for extrusion products such as foamed plates and micro-foamed plates of various specifications.

Recommended Dosage

Adjust according to actual needs: 3~5 PHR

(Note: PHR refers to Parts Per Hundred of Resin)

Packaging, Storage and Transportation

- Packaging: PE woven bag with inner plastic bag, 25KG/bag

- Storage and Transportation: Keep away from moisture; do not store or transport together with environmentally friendly products

General Formula

PVC | Filler | HB-88F | Lubricant | Processing Aid | Process |

100 | 25~100 | 3~5 | Appropriate amount | 1.5~2.5 | Extrusion Calendering |

Notes:Depending on the processing machine and formula, customers should appropriately adjust the dosage system of stabilizer and lubricant according to the increase in filler dosage.

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail