PVC Composite Heat Stabilizer HB-99 for Pipe Fittings

Description :

Main Components:

Tribasic Lead Sulfate, Lead Stearate, Lubricant, etc.

Physical Properties:

Characteristics:

Applications:

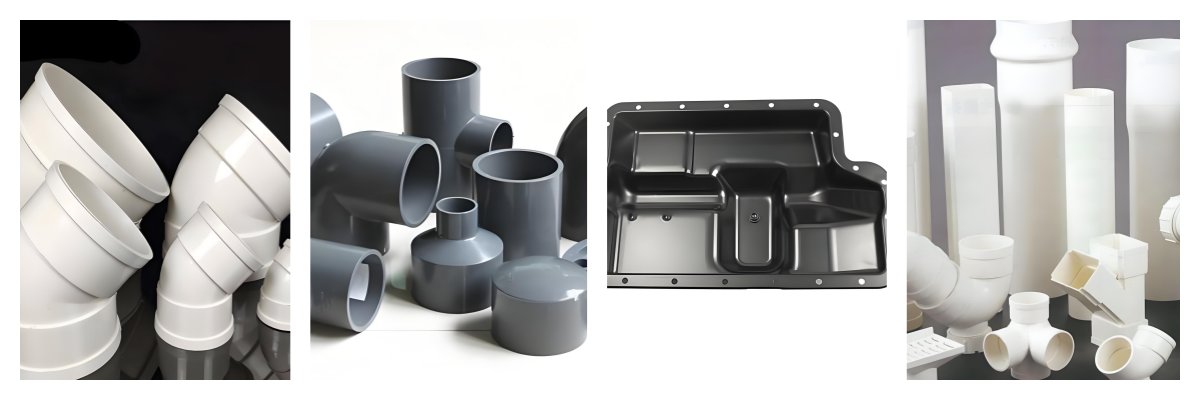

Used for injection molding products such as pipe fittings, elbows, and bottom casings.

Adjust according to actual needs: 2.5~4.5 PHR

(Note: PHR refers to Parts Per Hundred of Resin)

PVC | Filler | HB-99 | Lubricant | Processing Aid | Applicable Process |

100 | 20~75 | 2.5~4.5 | Appropriate amount | 1.5~2.5 | Injection Molding |

Note:Depending on different processing machines and formulas, customers should appropriately adjust the dosage system of stabilizers and lubricants according to the increase in filler dosage.

If you are interested in any product, please contact us. We will introduce our products to you in more detail